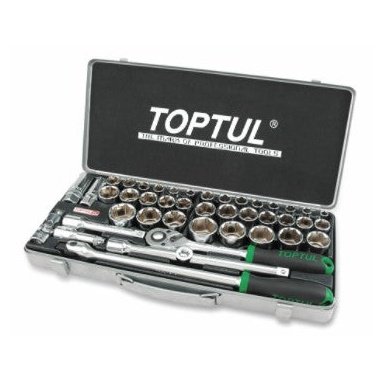

Standard and Deep Sockets

Standard sockets are the most common type and are suitable for most everyday tasks. Deep sockets have a longer profile, which allows them to reach fasteners that are recessed or located in awkward spaces.

Metric and SAE Socket Sets

Metric socket sets are designed for use with metric fasteners and are measured in millimetres. SAE (Society of Automotive Engineers) socket sets, on the other hand, are designed for use with Imperial (inch-based) fasteners and are measured in fractions of an inch.

Heavy Duty Impact Sockets

Our impact sockets are made from a more robust material, usually chrome-molybdenum steel, which enables them to withstand the high torque and force generated by impact tools. Designed to withstand the rigours of impact wrenches, these impact sockets ensure safety and longevity, preventing tool failure and injury.

Using regular sockets with an impact wrench can result in socket failure, potentially causing injury or damage to you. Our impact sockets, with their thicker walls and stronger construction, can handle the increased forces and vibrations produced by impact tools, ensuring a safer and more efficient work environment.

Making the Right Choice: Socket Sets and Impact Sockets

When choosing socket sets and impact sockets, consider the following factors:

- Material and construction: Ensure that the sockets are made from high-quality materials, such as chrome-vanadium steel for regular sockets and chrome-molybdenum steel for impact sockets.

- Drive size: Choose the appropriate drive size (1/4", 3/8", 1/2" or 3/4") based on your existing tools and the type of work you'll be doing.

- Measurement system: Determine whether you need metric or SAE sockets based on the fasteners you will be working with.

- Range of sizes: Select a set with a wide range of sizes to accommodate various fasteners and tasks.

- Quality assurance: Look for products marked with a Ray ID to ensure they meet the highest industry standards.

Shop Our Standard and Impact Socket Sets

At Tool Junction, we offer a comprehensive range of socket sets and impact sockets to suit your needs. With our wide selection, from standard to heavy duty, you can find the perfect set for your toolbox, whether you're a professional mechanic or a DIY enthusiast. Browse our collection today and experience the difference of quality and value that Tool Junction has to offer.

Rest assured, all our socket sets are designed with the necessary adapters and specifications for local use, even those in imperial terms. Invest in Tool Junction NZ’s long-lasting and trusted socket sets and impact sockets. Shop now.